Forged Irons

KZG has long been known for the quality of its forged irons and has received numerous awards of recognition from the industry and media. KZG forgings have been played on every tour by the very top players on tour … and we have never paid anyone to play our clubs. Several years ago, the most famous lefty on tour actually paid full retail for our KZG forged blades and he then tipped the fitter $200!

Forged irons are made by first heating a billet of virgin carbon steel to 1200 degrees Celsius and then forging it with a 50 ton forging hammer. The process is then repeated two more times by heating the metal to 800 degrees and forging with 50 tons of pressure. This process compresses the molecular structure of the metal so tightly it ensures no voids or inconsistencies in the iron head. We then CNC mill our heads to ensure precision specifications for each head. The results are forged irons that guarantee repeatable consistency, workability, feedback, great feel and pin-point accuracy.

Forged irons are made by first heating a billet of virgin carbon steel to 1200 degrees Celsius and then forging it with a 50 ton forging hammer. The process is then repeated two more times by heating the metal to 800 degrees and forging with 50 tons of pressure. This process compresses the molecular structure of the metal so tightly it ensures no voids or inconsistencies in the iron head. We then CNC mill our heads to ensure precision specifications for each head. The results are forged irons that guarantee repeatable consistency, workability, feedback, great feel and pin-point accuracy.

See our Forged Irons Overview here

Many golfers opt for cast irons as they believe that forged irons are only for the better golfer; some even think that forgings only come in blade style irons. This is simply not true. It is true forged irons cost more than cast irons so many golfers select the cast models. We have come a long way in making cast iron heads and KZG uses special metals and actually heat treats each head to get that “feel of forged” (stay tuned for a future post about our cast irons).

But if it is in your budget, there is still nothing better than forged irons. And if fit properly, the golfer can get many years of great play with them.

KZG offers ten distinctly different models of forged irons. The reason for so many models is that KZG only works with Master Fitters and those Fitters need to be able to select the design features they need to assure a perfect fit for their clients. And of course we offer a wide range of more budget friendly cast heads as well.

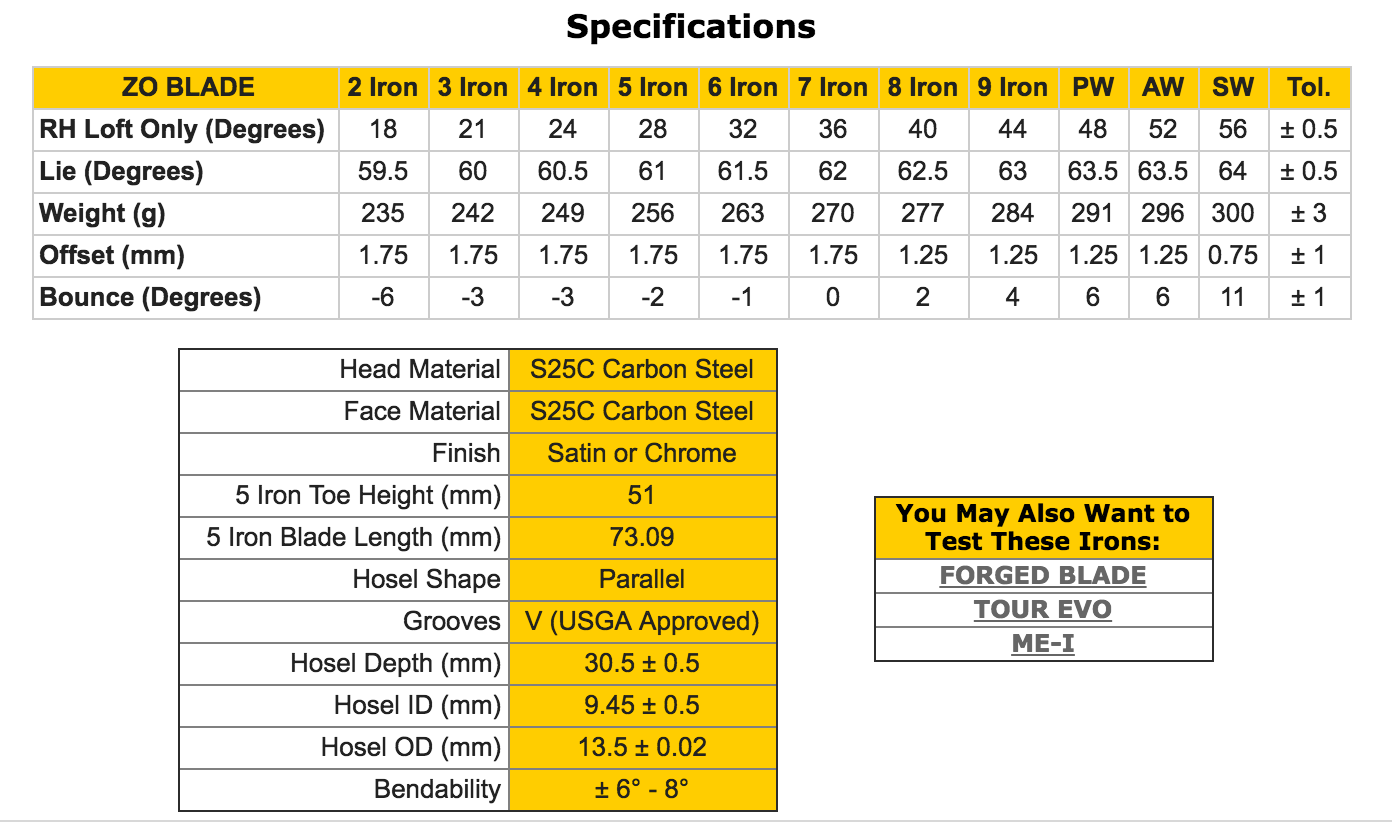

Here is a chart of the specs of our ZO Blade Irons